A piezo element, short for piezoelectric element, is a device that converts mechanical energy into electrical energy and vice versa. This fascinating phenomenon has been leveraged to create numerous applications in various industries. In this article, we'll explore the principles behind piezo elements and delve into some of their many applications.

How Piezo Elements Work

To understand how piezo elements function, we need to look at the two main concepts involved: the piezoelectric effect and the materials used in their construction.

Piezoelectric Effect

The piezoelectric effect is a property of certain materials that generate electrical charge when subjected to mechanical stress. Conversely, when these materials are exposed to an electric field, they undergo mechanical deformation. This remarkable characteristic is the basis for the operation of piezo elements.

Materials Used

Piezoelectric materials can be either natural or synthetic. Common natural materials include quartz, topaz, and Rochelle salt, while synthetic materials include ceramics like lead zirconate titanate (PZT) and polymers like polyvinylidene fluoride (PVDF). Each material has its unique properties that make it suitable for specific applications.

Applications of Piezo Elements

Piezo elements have found their way into a wide range of applications, including consumer electronics, medical devices, industrial applications, automotive industry, and aerospace and defense.

Consumer Electronics

In the consumer electronics sector, piezo elements are used in devices such as buzzers, microphones, and speakers. They are also found in inkjet printers, where they facilitate the precise ejection of ink droplets onto paper.

Medical Devices

The medical industry benefits from the use of piezo elements in devices like ultrasonic transducers. These devices are utilized in diagnostic imaging, such as ultrasound scans, as well as therapeutic applications like lithotripsy for breaking down kidney stones.

Industrial Applications

Piezo elements play a vital role in industrial applications, such as precision positioning systems, vibration sensors, and ultrasonic cleaning equipment. They also have a significant presence in the manufacturing of semiconductors and microelectronics.

Automotive Industry

In the automotive sector, piezo elements are used in fuel injectors for precise control of fuel delivery, improving engine performance and reducing emissions. They are also utilized in various sensors and actuators throughout the vehicle.

Aerospace and Defense

Piezo elements have numerous applications in the aerospace and defense industries, including gyroscopes, accelerometers, and vibration damping systems. They also contribute to active noise cancellation in military vehicles and aircraft.

Advantages and Disadvantages

Like any technology, piezo elements come with their share of advantages and disadvantages.

Advantages

High sensitivity and precision: Piezo elements can detect minute mechanical changes and produce electrical signals with high accuracy.

Low power consumption: They require minimal power to operate, making them suitable for energy-efficient applications.

Wide frequency range: Piezo elements can operate over a broad range of frequencies, making them versatile for various applications.

Durability: Due to their solid-state nature and lack of moving parts, piezo elements exhibit excellent durability and long life.

Disadvantages

Limited displacement: Piezo elements produce small displacements, which might not be suitable for applications requiring large movements.

High voltage requirements: Some piezo elements require high voltages for operation, necessitating additional power conversion circuits.

Temperature sensitivity: The performance of piezo elements can be affected by temperature fluctuations, which might require additional temperature compensation mechanisms.

Future of Piezo Elements

The future of piezo elements appears promising as new materials and manufacturing techniques continue to be developed. The ongoing research in this field aims to improve the efficiency, sensitivity, and temperature stability of these elements. As a result, we can expect to see even more innovative applications of piezo technology across various industries in the coming years.

Conclusion

Piezo elements have come a long way since their discovery and have proven to be invaluable in many industries due to their unique properties. As research and development continue, we can expect to see even more exciting advancements in this technology, further expanding its applications and benefits.

A piezo element is an alternative electronic component that can be adapted to different fields by changing its size. In general, the frequency of vibration of a piezoelectric element depends on the magnitude of the input current, which plays a role in the process of converting electrical energy into mechanical energy, which is determined by the physical composition and shape of a given material.

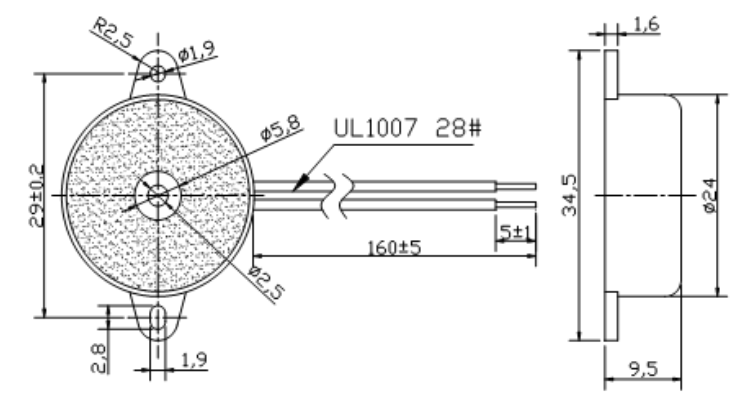

Type | Unit | MSPS24C35W12 |

Rated Voltage | VDC | 12 |

Operating Voltage | VDC | 3~18 |

*Rated Current | mA | Max .15 |

*.Sound Output at10cm | dB | Min .85 |

*Resonant Frequency | Hz | 3500±500 |

Operating Temperature | ℃ | -20~+70 |

Storage Temperature | ℃ | -30~+80 |

Acoustic piezoelectric devices are now in great demand because they have multiple uses in every aspect. Piezo buzzers are such a wide range of acoustic piezoelectric components. It is especially used for alarm equipment, which can provide clear sound. If you are a user who needs an alert device, this is definitely your best choice. Not only is it reasonably priced, it also offers an expanded range of uses.

The sound quality of the piezoelectric buzzer is absolutely qualified and excellent. This is especially true for piezo buzzers designed and manufactured by professionals. As a buyer of this electronic acoustic component, you need to carefully study some key features of the product before purchasing. Frequency is undoubtedly one of the characteristics of high-quality piezoelectric components. The perfect frequency is the main factor for the sound pressure generated by the buzzer. This means that the plastic case and piezoelectric bender should have matching frequencies.

Tone is the second characteristic to consider when purchasing a piezoelectric buzzer. The tonal nature of the device can take many forms, such as continuous or pulsed. Of course, in other buzzer series, we will also explore other types. In short, when it comes to the sound of the buzzer, your preference should determine your choice.

We should also consider the shell of the buzzer. You need to review and understand the materials used as the buzzer housing. Different materials have different characteristics. It should be durable enough to withstand pressure from different environments. At the same time, you need to consider how to install the piezoelectric buzzer. The correct installation configuration can ensure excellent sound transmission.The material of the buzzer shell is mainly plastic, including LCP, ABS, PBS, PBT, PPO, PVC, etc. Afterwards, our company will have related articles in this regard for your reference.

Over the years, continuous research has made the application of piezoelectric elements simpler and more efficient, and industrial manufacturing has also undergone revolutionary changes.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

অসমীয়া

Беларуская мова

Basa Jawa